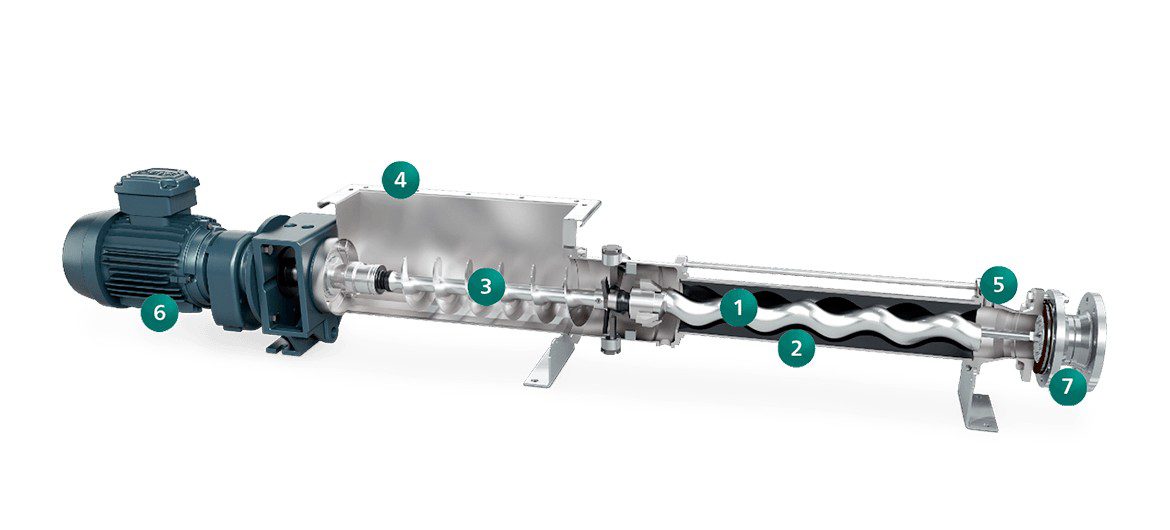

BO/SO Hopper Pump with Cutting Device

Conveying and cutting in one process step without expensive additional equipment, this is exactly what the hopper pump with integrated cutting device makes possible. With the progressing cavity pump, for example in the food industry, large solids such as pieces of fruit or vegetables can be easily and quickly chopped and pumped for further processing.

The BO/SO progressing cavity pump with hopper and coupling rod with feeding screw and force-feed chamber is employed in almost all branches of industry to provide continuous, pressure-stable, gentle and low-pulsation conveyance. The hopper housing with cutting unit guarantees optimum feed of chunky medium into the conveying elements. If the medium passes the force-feed chamber with the cutting unit the larger fruits and vegetables are cutted immediately. This unit consists of a rotating knife with three blades and a variable number of stationary knives adjustable to the size and consistency of the particles. Optionally the pump can be equipped with an additional cutting unit at the discharge flange of the pump. With its perforated disc and rotating knife it allows for further fine definition of the particle size. As any other progressing cavity pump also the BO/SO pump has the ability to dose the conveyed media in proportion to rotation speed. In block construction with a flanged drive, this pump is particularly compact and economical In addition, the pump is characterised by low investment, operating and maintenance costs. However, it is also available in bearing block design with a free shaft end. This means that the pump can be operated with different types of drive, such as servo motors, diesel engines or hydraulic drives.

ADDITIONAL INFORMATION

Design Features:

- Rotor – In wear- and corrosion-resistant designs including the wear-free ceramic rotor

- Stator – Vulcanized into the tube with sealing on both sides in a variety of elastomers, plastics and metals. Stator inlet with hopper-shaped opening for improved feed of the product into the conveying chamber.

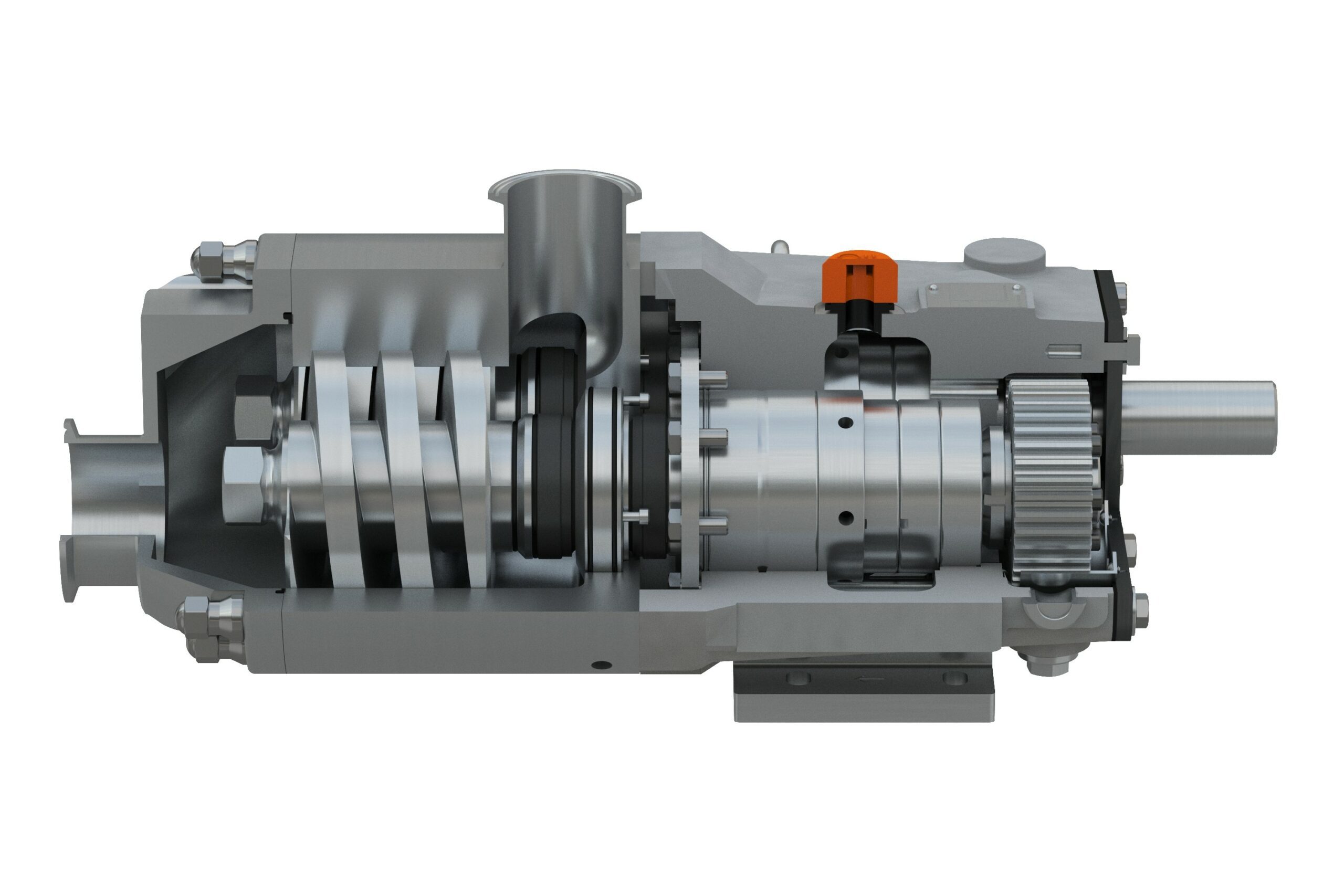

- Power train with optional cutting unit – Coupling rod with screw conveyor to improve product feed into the conveying elements and two cardan joints to transmit power from the drive to the rotor. The optional cutting unit, mounted in the forcefeed chamber, consists of a rotating knife with three blades and a variable number of stationary knives, which are adjusted according to the shredding requirements.

- Shaft seal – Standard with single-acting, bi-directional, wear-resistant mechanical seal. Upon request, with single- or double-acting mechanical seals of varied designs and from various manufacturers, cartridge and special seals as well as packed glands.

- Suction and discharge casing – Pump housing with rectangular hopper and screw conveyor with forcefeed chamber. The hopper dimensions can be adapted to the individual application. Flange and threaded connections in accordance with DIN and international standards. Materials in cast iron, steel, chrome-nickel-steel rubberized; also special materials upon request. With optional cutting unit option with removable forcefeed chamber.

- Block design – The drive is flanged directly to the lantern of the pump, resulting in compact dimensions, low total weight, constant axial heights irrespective of the construction type and size of the drive, and ease of maintenance and serviceability as well as high efficiency.

- Optional cutting unit on the discharge flange – The cutting unit on the discharge flange, consisting of a perforated disc and a rotating knife, determines the particle size of the material leaving the pump on the discharge side.