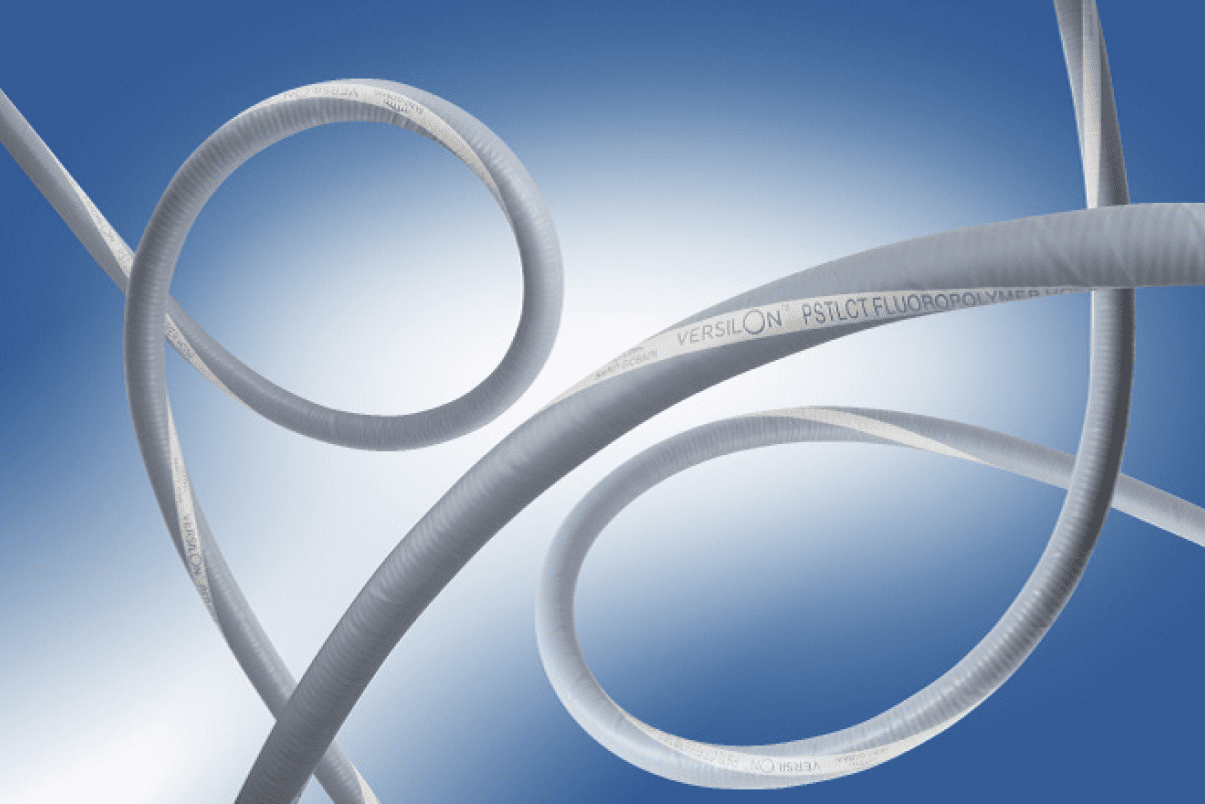

Pharmaline N Hose

| Manufacturer | Aflex Hose |

|---|---|

| Product Line | PharmaLine |

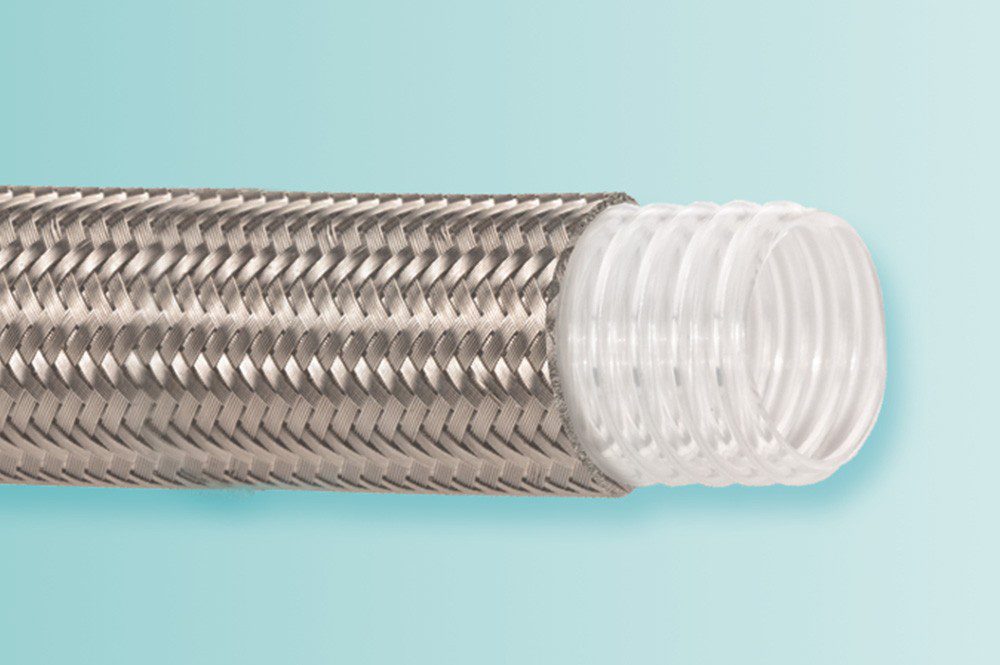

Aflex Pharmaline N is a unique, genuinely smooth bore PTFE lined hose product, based on the same patented PTFE hose liner design developed for Aflex Bioflex hose. Pharmaline N is designed to overcome the very poor flexibility of silicone rubber covered smooth bore PTFE hose products. Aflex Pharmaline N is also designed to offer a replacement for silicone rubber hose providing much better chemical resistance and steam resistance much improved ease of cleaning. Pharmaline N hose assemblies are manufactured in ‘clean room’ conditions and meet USP VI, FDA and all other specification requirements. Aflex Pharmaline N includes a stainless steel wire braid to reinforce the hose construction against internal pressure and mechanical abuse in applications which require this. Pharmaline’s N braid is covered with an extruded, pure white silicone rubber with a smooth, easy-clean surface finish.

Get Your Sanitary Hoses In 48 Hours

Holland can deliver sanitary hoses quickly. Provide our team with the hose specifications, we’ll provide a quote and ship your hoses within 48 hours.

ADDITIONAL INFORMATION

| Size Part No. | Nominal Bore Size (in) | Actual Bore Size (in) | Outside Diameter (in) | Minimum Bend Radius (in) | Max Working Pressure (Psi) | Burst Pressure (Psi) |

|---|---|---|---|---|---|---|

| 04 | 1/4 | 0.260 | 0.460 | 3/4 | 1160 | 4641 |

| 06 | 3/8 | 0.382 | 0.610 | 1 | 1015 | 4061 |

| 08 | 1/2 | 0.516 | 0.845 | 1 1/2 | 870 | 3480 |

| 10 | 5/8 | 0.638 | 0.990 | 2 | 725 | 2900 |

| 12 | 3/4 | 0.760 | 1.120 | 2 1/2 | 655 | 2610 |

| 16 | 1 | 1.012 | 1.455 | 4 | 580 | 2320 |

| 20 | 1 1/4 | 1.268 | 1.755 | 5 1/4 | 510 | 2030 |

| 24 | 1 1/2 | 1.516 | 2.035 | 6.7 | 435 | 1740 |

| 32 | 2 | 2.012 | 2.580 | 8.27 | 405 | 1624 |

| 40 | 2 1/2 | 2.508 | 3.169 | 11.81 | 290 | 1100 |

| 48 | 3 | 3.024 | 3.654 | 13.78 | 218 | 870 |

Pharmaline N GP Grade

GP is the ‘General Purpose’ grade, for use in all applications where fluids or gases are being conveyed which do not generate a risk of static charge development (see “AS”).

Design & Approval:Aflex PharmalineGP Grade has a virgin PTFE liner, manufactured from hose grade PTFE which conforms to the requirements of:FDA 21 CFR 177.1550 Both the PTFE liner tube and the platinum cured silicone rubber cover have been tested and conform to the requirements of USP Class VI both at normal temperatures and at 121˚C (250˚F) . Pharmaline hose (but not Pharmalex Hose) in sizes 3/4” and above includes a Grade 304 SS wire helically wound in the external convolutions, to reinforce the hose against kinking.

EC – ELECTRICAL CONTINUITY:Electrical continuity requires that the hose assembly supplied is electrically continuous, or conductive, between metal end fittings at each end of the hose. This can apply whether the hose is GP or AS grade. The requirements for electrical continuity are specified in the German Document BRG132, and the Specification EN ISO 12115, tested to EN ISO 8031 Clause 3.7, which requires that for hose assemblies with a resistance between fittings of <102 ohms, a letter “M” can be applied, or <106 ohms, a letter “Ω” can be applied. Aflex Pharmaline Hose Assemblies are all electrically continuous, and all meet the requirements of both “M” and “Ω”, but are not stamped unless requested.

Pharmaline AS Grade

Aflex Pharmalne AS Grade is an essential requirement in applications where there is the risk of an electrostatic charge build-up on the inside surface of the PTFE tube which may then discharge through the tube wall. Media passing through which create such a risk are fluids which have a Conductance of less than 10-8 S/m (Siemens per Metre), or 104 pS/m such as fuels, solvents, freons, some WFI (ultra-pure “Water for Injection”) and non-polar organics which are being transferred at a medium to high flow velocity. All twin or multi phase media, and any non-mixing media, such as powder in air, or water droplets in steam, in gases or in oil, also colloidal fluids constitute a particular hazard for static charge generation, and always require grade AS.

Design & Approva:l Pharmaline AS Grade hose has an anti-static PTFE liner manufactured from FDA approved PTFE, and less than 2.5% of “high purity” Carbon Black material to FDA requirement 21 CFR 178.3297 and European Commission Directive 2007/19/EC. AS Grade also conforms to the requirements of USP Class VI both at normal temperatures, and at 121˚C (250˚F)

Specifications: When Pharmaline “AS” (Antistatic) grade hose is specified, then the hose supplied will be in accordance with the requirements of BS5958 Part 2, 1991 Clause 19.3, when tested in accordance with EN ISO 8031 Clause 3.1, which requires that the resistance between a plug inserted 25mm into the bore at the end of the hose assembly, and one of the metallic end fittings should be less than 108 ohms.

NOTE: When in service, at least one end fitting must be connected to earth, to permit dissipation of the static charge from the end fitting.

Aflex Pharmaline Hose Approvals

- Natural and Antistatic PTFE Hose Liners, Platinum Cured Silicone Rubber Covers (White and Clear) and EPDM Rubber Cover (Blue) have been independently tested in accordance with USP protocols and are found to conform to the requirements of USP Class VI Chapter 88.

- Natural and Antistatic PTFE Hose Liners on Pharmaline now also meet the more stringent USP Class VI and ISO 10993-6,10 and 11 guidelines at 121°C (250°F) with a ‘no reaction’ classification.

- Natural and Antistatic PTFE Hose Liners and Platinum Cured Silicone Rubber Covers (White and Clear) have also been tested in accordance with USP protocols and are found to conform to the requirements of USP Class VI 87, the L929 MEM Elution Test and are considered non-cytotoxic.

- Natural and Antistatic PTFE Hose Liners have now been further tested and have passed the more stringent USP Class VI and ISO 10993-5 guidelines at 121°C (250°F).

- The Materials used to manufacture the natural PTFE Tube liner on Pharmaline conforms to FDA 21 CFR 177.1550, and the antistatic PTFE liner conforms to FDA 21 CFR 178.3297.