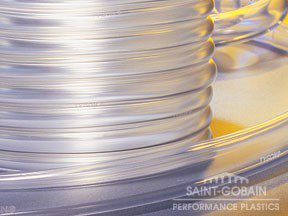

C-Flex TPE Tubing

| Manufacturer | Saint-Gobain |

|---|---|

| Product Line | C-Flex |

Saint-Gobain’s C-Flex® is a unique, patented thermoplastic elastomer tubing specifically designed to meet the critical demands of the medical, pharmaceutical, research, biotech and diagnostics industries.

C-Flex® biopharmaceutical tubing has been used by many of the world’s leading biotech and pharmaceutical processing companies for over 20 years. Each coil of C-Flex tubing is extruded to precise ID, OD and wall dimensions . All C-Flex tubing is formulated to meet the standards of the biopharmaceutical industry and is QA tested before leaving our production facility.

ADDITIONAL INFORMATION

C-Flex® Tube Typical Applications

- Aseptic sealing disconnections

- Aseptic welding connections

- Ideal for use in single-use assemblies

- Buffer and Media preparation

- Cell culture operations

- Purification Operations

- Diagnostics Products

- Biopharma Manufacturing

- Single-use fluid transfer sets

- Tubing and bags manifold

- Laboratory R&D

- High-purity water system

C-Flex® Tubing Physical Properties

| Formulation | 374 | 072 | 082 |

|---|---|---|---|

| Durometer, Shore A (5 SEC. ASTM D2240) | 60 | 60 | 60 |

| Appearance | Clear | Opaque | Clear |

| Tensile Strength, psi (ASTM D412) | 1190 | 1462 | 1190 |

| Elongation, % (ASTM D412) | 708 | 679 | 708 |

| Tensile Modulus, @100%/300%, psi (ASTM D412) | 230/380 | 240/360 | 230/380 |

| Tensile Set, % at break | 92 | 75 | 92 |

| Tear Resistance, lb/in., Die C/Die B | 175/130 | 180/135 | 175/130 |

| Compression Set Constant Defl.,”B” (22 hrs. @ 70°C), % | 57 | 60 | 57 |

| Abrasion Resistance, mg. lost/1000 cycles | 9.0 | 5.7 | 9.0 |

| Specific Gravity (ASTM D792) | 0.90 | 0.90 | 0.90 |

| Water Absorption, % at 100% RH (ASTM D570) | 0.2 | 0.2 | 0.2 |

| Brittle Point, °F | -88 | -100 | -88 |