Why Sanitary Centrifugal Pumps do not use Closed Impellers

Centrifugal pumps are the work horses of the fluid process world. They are used everywhere from the petro chemical industry to municipal water and wastewater systems, to the sump pump in your basement. If you spend time on the internet (obviously you do or you wouldn’t be reading this), you can find a wealth of knowledge about centrifugal pumps and pump applications. Then there is our little niche of the process world, the sanitary market. Interestingly the volume of good information on sanitary centrifugal pump and applications is much more limited. With our blog, Holland has been making a conscious effort to change that, and we continue on with an overview of sanitary centrifugal pump impeller design.

One of the big buzz words in corporate America today in sustainability. Companies are making a big push to make more environmentally friendly products and packaging, emit less waste/pollution, and consume less energy. Who could argue with that? So what has that got to do with pumps? We will explain.

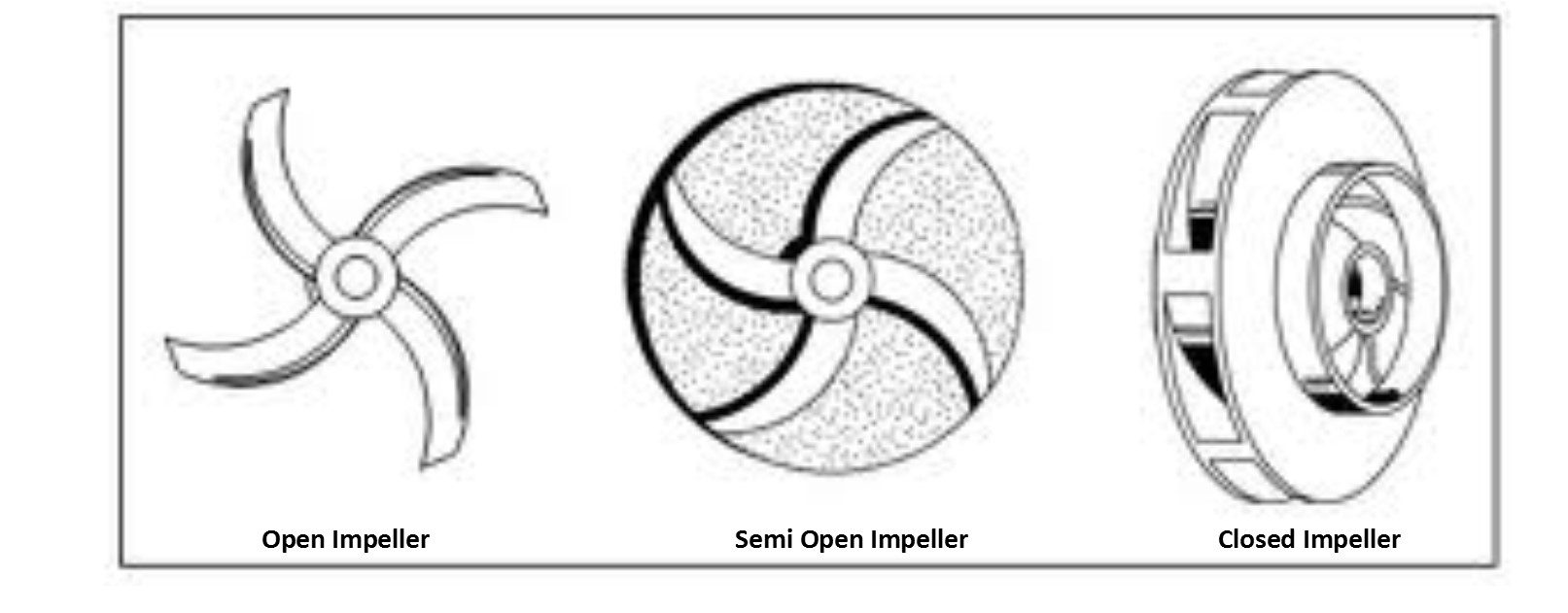

Originally all centrifugal pump had open impeller designs. They consisted of a central hub with individual vanes going out from the hub. In an effort to improve efficiency, manufacturers developed the semi-open impeller where the impeller has a solid shroud on the back of the vanes. Then finally the closed impeller was developed.

The closed impeller has shrouds on both the front and back of the vanes. Closed impeller centrifugal pumps have wear rings that separate the suction from the discharge side of the pump. These pumps are very efficient. They eliminate any areas for leakage loss across the vanes. These pumps also do not require tight tolerances to be set between the impeller and the pump casing. Finally, because the vanes are supported on both sides they, can be made of thinner material. This increases the flow area through the impeller.

Sounds great, sign me up. Where do I get my sanitary centrifugal pump with the closed impeller design? Well, you can’t. While they are efficient there is one thing closed impellers are not, cleanable. To be considered sanitary, a pump needs to be cleanable. Closed impeller pumps have areas within the housing that do not receive enough flow to render them clean in a CIP cycle. Also, to manufacture a stainless steel closed impeller without bacterial entrapment pockets is almost impossible, not to mention cost prohibitive.

So where does that leave you? You try and do the right thing. You recycle. You quit using plastic water bottles. You drive a Prius. You want to be sustainable, but you need a sanitary centrifugal pump. The standard sanitary centrifugal pump used for years, the venerable “C” Series pump has a stamped casing and a completely open impeller design. While very clean and inexpensive, this is not a very efficient design. Because the stamped casing flexes under pressure, the tolerances within the pump have to be very big to ensure the impeller does not scrape the casing.

The most efficient sanitary centrifugal pumps on the market today have open impellers with partial shrouds on the back of the impeller. They have heavy duty casings and tight tolerances, while still maintaining their cleanability characteristics. These are much more efficient than older sanitary centrifugal pumps. Waukesha, Fristam, APV and Alfa Laval all have pumps with more efficient designs. As an example, in an application pumping water at 200gpm at 150ft of discharge head a C216 pump is 64% efficient. At the same data point a Waukesha 200 Series 2065 has a 70% efficiency rate.

The C Series Open Impeller on the Left, the Semi Closed Waukesha 200 Series Impeller on the Right. Notice the Holes Around the Center of the 200 Series Impeller. These are there to Allow the Area Behind the Impeller to Clean Properly

So if you want to be “sustainable” and need a sanitary centrifugal pump, take a look at the newer designs. Also, and just as important, make sure once you have decided on a pump model, choose the pump that has the high efficiency in regards to the casing and impeller sizes. Reference our blog on centrifugal pumps curves for more on this.

Call us at 800-800-8464 on this or any other topic regarding sanitary process or contact us via our web site.